AT BOOTH’S OUR MOTTO IS B SAFE

Nothing matters more than making sure everyone who works or drives with us gets home safely each day to their Top 5 – the five things in life they enjoy most.

We’re committed to reducing incident rates across our business, with a strong focus on high-risk activities through our Critical Risk Program.

This commitment is backed by nationally recognised certifications that reflect the strength of our systems and the standards we hold ourselves to.

Nationally recognised accreditations, certificates and systems

ACC Fleet Saver programme – Gold status

This prestigious recognition highlights our excellence in fleet safety management.

It demonstrates our commitment to continuous improvement and acknowledges the strength of our safety systems.

Totika certification – Championing safety excellence

Totika is New Zealand’s national health and safety pre-qualification framework. Booth’s certification confirms the high-performing standard of our systems and reinforces our commitment to health, safety, and quality across all areas of the business.

BRCGS Storage and Distribution – Wellington warehouse

BRCGS Storage and Distribution is an international standard ensuring the safe storage and distribution of products. It covers handling, storage, and distribution of goods, focusing on maintaining product quality and safety throughout the supply chain.

Our warehouse in Wellington is certified for BRCGS.

Dangerous Goods storage

Booth’s has decades of experience safely handling and storing a range of dangerous goods.

A wide range of industrial warehousing and storage solutions for hazardous materials are available, backed by highly trained staff, accredited processes and network of dangerous goods storage facilities.

Our warehouse in Hastings and Tauranga is certified to hold large volumes Class 6 and 8.

Approved transactional facility

Booth’s Logistics are approved as a transitional facility to conduct biosecurity inspection and devanning of import containers.

We have 13 registered facilities across nation each with different capability.

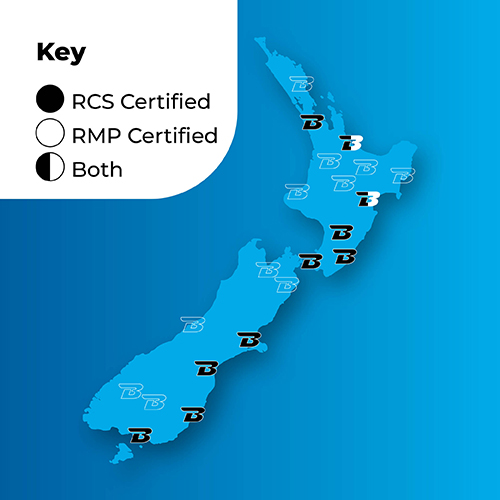

Regulated Control System (RCS) and Risk Management Programme (RMP) capabilities

Booth’s operates nationwide under the Regulatory Control Scheme (RCS – CAN3) to transport export-quality animal products, including dairy, meat, honey, and pet food. We offer goods transfers at registered depots and container loading at our Export Loading Facilities (ELF).

Our RMP-approved sites ensure secure storage and transport of animal products. We also hold MPI/Council registration under National Programme Level 1 for nationwide food storage, distribution, and transport.

Safety technology

Keeping our people safe – both on the road and on site – means using the right technology in the right way.

Our team is supported by:

- Electronic logbooks for accurate records and compliance

- In-cab systems that provide real-time insights into driver alertness and vehicle behaviour

- Digital pre-start checks to make sure every truck is ready to go

- EcoPortal, our cloud-based health and safety management system empowers our workforce to make safety and quality a shared responsibility.

- EROAD Clarity dashcams with fatigue and distraction monitoring

Chain of responsibility

At Booth’s, health and safety is built on the understanding that everyone has a role to play. Whether you’re in the yard, the office, the workshop, the warehouse, or out on the road – every team member contributes to maintaining our chain of responsibility.

How we lead:

- A modern fleet fitted with advanced safety features and fatigue detection technology

- A tailored health and wellbeing programme that encourages healthier choices for drivers

- A peer-led training system where experienced drivers’ mentor new team members

- A robust subcontractor management process to ensure everyone meets our strict Chain of Responsibility (CoR) standards

Measuring safety

We believe safety should be practical, visible, and part of everyday operations for both our team and our partners. We track safety performance using a range of tools and indicators to make sure we’re always learning and improving.

What we use:

- Critical risk tracking through our STiCKY system

- QR code-based reporting for fast, on-the-go submissions

- Visual training content delivered by our ‘Buddy’ system

- Learning teams led by frontline staff

A family-owned freight and logistics company, we have the resources to flex with your needs and the nationwide reach to be where you need.

Get in touch

Partner with us

Tell us what you’re looking for and we’ll get back to you with how we can help.

Ask us

Reach out with any enquiries, questions or feedback, we’re always happy to hear.

Linehaul

Linehaul Metro

Metro HIAB

HIAB Warehousing & Third Party Logistics

Warehousing & Third Party Logistics

Container Transport & Handling

Container Transport & Handling

Import Devan & Export Unloading

Import Devan & Export Unloading

Flat Deck

Flat Deck Specialty

Specialty